Introduction

The need of building occupants for ventilation has been recognized many centuries ago; however, since the early 1970s, ventilation systems for buildings and transport systems have considerably evolved. This was invigorated by researchers who demonstrated the requirements for buildings to provide comfort and good air quality indoors (e.g., Fanger, 1972; Fanger and Christensen, 1986; Fanger, 1988; European Collaborative Action, 1992). Later on, this need evolved to address the additional energy requirement for buildings to achieve the indoor environment quality levels stipulated by those previous researchers (Awbi, 2003, 2007; Karimipanah et al., 2007, 2008).

Energy consumption for heating, cooling, and ventilating buildings often accounts for the largest part of a country’s energy usage, which is still mainly based on fossil fuels. There is a great global emphasis on reducing the reliance of buildings on fossil fuel energy and a move toward Nearly Zero Carbon Buildings (NZCB). This requires a major shift in the way buildings and their integrated heating, cooling, and ventilation systems are designed, operated, and maintained. Achieving this goal will require a rethink of the traditional designs of and types of systems currently in use. The proportion of ventilation energy in comparison with the total energy use in a building is expected to increase as the building fabric energy performance improves and ventilation standards recommend higher ventilation rates for improving indoor air quality (IAQ). At the same time, new building regulations (Directive 2010/31/EC, 2010; Building Regulation, 2010) are imposing air-tight construction, which will inevitably impact on IAQ, health (e.g., sick building syndrome), and human productivity in some future buildings (Seppänen, 2012).

Despite recent advances in building ventilation (Nielsen, 1993; Etheridge and Sandberg, 1996; Skistad et al., 2004; Awbi, 2011; Müller et al., 2013), it is evident that complaints about poor IAQ have increased in recent years (Gunnarsen and Fanger, 1992; Fisk, 2000, Bakó-Biró, 2004; Fanger, 2006; Boestra and van Dijken, 2010). There is a need therefore for assessing current methods of building ventilation and developing ventilation systems that are capable of providing good IAQ and energy performance to satisfy building occupants and meet new building energy codes.

This article gives a brief overview of the various types of mechanical ventilation and air distribution systems that are used for buildings; highlighting those systems that are capable of providing better IAQ and energy efficiency. The aim is to provide some insight to those building professionals whose tasks are selecting ventilation systems for low energy buildings that can provide the necessary levels of IAQ for the occupants; and for the research community to continue research in this area in order to develop new ventilation concepts and deliver the desired performance.

Status of Mechanical Ventilation and Air Distribution Systems

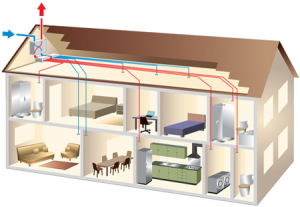

Ventilation is the process of replacing contaminated indoor air with fresh air from outside the building. This can be fortuitous in the form of air leakage through cracks and openings in the building envelop (air infiltration) or purposely provided ventilation in the form of natural, mechanical, or a combination of the two (hybrid or mixed-mode). In mechanical ventilation, the airflow is distributed by means of fans and ductwork arrangement throughout the building and then distributed in the room via air terminal devices or diffusers. The focus of this article is on the current status of mechanical room air distribution systems with a particular emphasis on recently developed methods of air distribution.

Various methods of mechanical ventilation and room air distribution have been implemented and used in different types of buildings over many years now. Some of these classical methods are still widely used, such as mixing ventilation (MV), but new concepts are currently being developed for wider commercialization, such as the impinging jets (IJ) and the confluent jets (CJ) systems. In a standard design of the air distribution system, the building (or room) is often considered as an empty space with allowance made for internal heat sources and external heat gains/losses but no account is normally given to localized heat sources and thermal plumes arising from them. In many cases, thermal plumes can have a major impact on the air movement not only in the case of displacement ventilation (DV) (which are its driving force) but MV too (Cho and Awbi, 2007). In practice, a simplistic design approach for ventilation systems that does not consider thermal plumes for instant could often lead to inappropriate performance in terms of air quality provision and energy performance.

A brief summary of some of the different methods of room air distribution, both the conventional and less conventional, is given below. Such systems can be categorized into six main types depending on the method of air supply and extract from the room (room air distribution). Each method is characterized by the airflow pattern it produces in the room and the location of the air supply/exhaust devices. More detailed information on available mechanical systems can be found in Cao et al. (2014) but the focus here is on those systems that are widely used or have the possibility of wider applications in future.

Mixing ventilation has been in use longer than any of the known mechanical ventilation systems and it is well documented in various ventilation guides and standards (e.g., ASHRAE Handbook, 2011). The principle behind a MV system is to mix fresh air with contaminated room air to reduce the contaminant concentrations in a room. Here, an air jet is normally supplied at the upper parts of the room (ceiling or wall at high level) at a high velocity (typically >2.0 m/s) to provide air jets circulation around the room peripherals. Some air supply methods that are based on MV are given in Table 1. Normally, the airflow rates are determined by the number of air changes for the room, which is determined by cooling and heating loads for that room. With a properly designed system, the resulting temperature and contaminant concentration in the occupied zone (up to 1.8 m height) should be quite uniform. Although this is a widely used air distribution system, it is known that it is not very efficient in terms of good air quality provision and energy performance (Karimipanah et al., 2008).

Future Development in Ventilation and Air Distribution

As mentioned earlier, room air distribution and ventilation techniques have greatly been improved in the last 40–50 years. However, this important field of HVAC, which has a direct impact on people’s health and productivity, has the potential for greater development as some commonly used methods are not always suitable for delivering the IAQ demanded by the building occupants and at the same time meeting stricter energy performance guidelines. As increased awareness of the impact of ventilation on human health and productivity is expected to become more topical, it is anticipated that more advances in the delivery of fresh air to occupants will be foreseen to meet people’s aspirations. It would be expected therefore that:

• the unconventional methods of room air distribution will become more commonly used;

• wider application of demand control ventilation (DCV), i.e., a direct link of fresh air supply to IAQ;

• more reliance on using simulation tools for visualizing room air movement, such as computational fluid dynamics (CFD), to improve our prediction of the performance of ventilation systems at the design stage;

• a move toward more energy efficient methods of room air distribution;

Reference: http://journal.frontiersin.org/article/10.3389/fmech.2015.00004/full